An F less, but more resistant

Silicone Sealants | FIPG

In addition to our proven, high-performance 2-component PUR seals (FIPFG), we use 1-component seals for other important areas of application for our clients. For example, they would be used if your application requires high temperature and/or chemical resistance, or the seal should be less compressible than a foamed seal. Our single-component elastic solutions are even used for electrically conductive seals. We dose silicones, polyurethanes or MS polymers in pre-reaction liquid form directly onto your component. They are precisely contoured to the smallest shapes, extremely adhesive and durable.

Areas of application

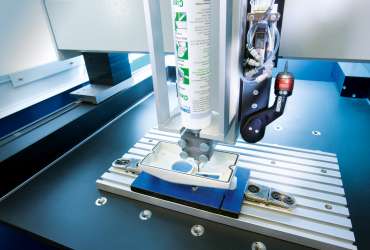

Perfect sealing - directly onto the component

Sealing, gluing, potting. Precisely contoured and applied directly to your component. We enable our customers to use these methods in mass-production thanks to our cutting edge dosing systems. With our three-axis and six-axis robots, our set of machine tools is among the most modern in Europe and the largest in this service area.

We can seal your housing, switch cabinets or light units, apply adhesives or pot electronic components.

Sealing

Formed in place and perfectly dosed

Our formed-in-place seals are precisely geared to your requirements and the technical specifications of your application. We can also offer you single-component EMC (electromagnetic compatibility) seals, for example if you want to prevent magnetic or electric interference with your component. This generally means using sealing systems filled with conductive particles.

Application can take the form of a compact 1-component seal, or also a combination of two 1-component seals. In the latter case, a softer, non-conductive silicon bead (core) is applied at the same time as the conductive variant (shell). The advantage for your customers is a clear cost saving and higher compressibility thanks to the softer core, with comparable levels of conductivity.

Gluing

The search for a connection that lasts forever

Gluing must be the oldest joining process in the history of mankind, but experience shows that it still poses daily challenges. For durable adhesion, it is vital to choose the right gluing system. In the production process to be determined (as in the case of welding and soldering), it is not possible to evaluate the quality of the adhesion of the glue to the bonding partners with non-destructive tests.

Technical specifications and the level of adhesion must be defined and released in advance. We will work with you to find the appropriate product from our 1-component and 2-component solutions.

Potting

An even better seal.

More extreme demands or component properties may require more than just a perfect seal integrated in casing. In this case, we pot the entire component. If the component itself does not prevent the potting flowing away, the dam-and-fill method can be applied. A lot can also be achieved using chemical tricks in combination with the programmable dosing systems. 1-component and 2-component systems can be used to get the best possible seal.

A component can also be sealed to hide our client’s specialist knowledge. Semi-transparent seals can hide the interior while allowing for optical signals. Potting can also be used to protect against vibration or to make the component look or feel more high-quality.

Materials

Polyurethane (PUR)

1-component and 2-component polymers that can be used as potting or foamed or non-foamed elastomer seals with excellent resilience. They can withstand temperatures from -40°C to + 80°C, even 120°C for extreme applications.

The dual-component systems used at KÖPP are softener-free and have good chemical resistance. Formed-in-place PUR seals are commonly used for switch cabinets, lights and the automotive sector.

Silicones (also EMC systems)

Silicones can also be used as 1-component or 2-component systems. This type of system is often chose because the application involves elevated temperatures and resistance requirements.

Filigree seals can be applied, on top of each other if appropriate, or EMC systems can be used.

MS polymers

MS polymers are silane-modified, moisture-hardening polymer seal or adhesive systems. They are highly flexible and highly elastic, and they stand out for their good adhesion to substrates such as metal, ceramics, glass, rubber, plastics etc.

It is often possible to dispense with a primer; this is not the case with many silicone or PUR adhesives. MS polymers are also highly temperature and UV-resistant. They do not contain any isocyanates and they can be used in silicone-sensitive applications.

Epoxy resins

As an alternative to the PUR potting systems described above, epoxy resins can also be applied in the 2-component process, as potting or as adhesive. Selecting the appropriate resin and hardener can create systems with high mechanical and thermal stability and chemical resistance, which can harden within a period from a few minutes to a few hours.

Important for stress-free hardening. Epoxy resins are often used in the electronics industry because of their good dielectric properties.

Customers are increasingly using outsourcing

Our customers entrust their workpieces to us to apply our FIPG systems. Of course, our services include careful handling of the components, precise checks, appropriate interim storage and precise, professional shipping of the finished parts.

With our experience as Europe’s larges service provider for formed-in-place liquid seal systems, gluing applications and potting technology and our extensive storage and logistics capacity, an increasing number of mass-producers use our services. This is sometimes even the case when the high number of units might seem to indicate it would be worth investing in an in-house system. You too can use the outsourcing model to stay flexible.

Technical data

| Parameters | Silicone | MS |

|---|---|---|

| Number of components | 1 | 1 |

| Cross-linking* | RTV system | RTV system |

| Seal shape T/mm | Minimum 0.8 | Minimum 0.8 |

| Temperature resistance | -50 to +250°C | -40 to +90°C, for short periods 200°C |

| Resistances | Very good | Good - excellent |

| Adhesion | Excellent, even on glass | Excellent, can even be used as glue |

| Viscosity | Mostly high-viscosity, stable | Medium-viscosity, stable |

| Hardness Shore A | 15-45 | 40-60 |

| Stress-strain compression (25% compression) | - | - |

| Tensile strength N/mm² | - | 1.9 - 3.3 |

| Elongation at break in % | 250-750% | 310-650% |

| Tearing strength N/mm² | 1.5-4.5 | |

| Density g/cm³ | approx. 1-1.5 (up to 2.5 with EMC) | 1-1.6 |

| UV and ozone-resistant | ja | ja |

| Colour | Transparent, white, black, red, beige | White, grey, black, transparent |

| Flame retardant, UL 94 | Special types | - |

| Approved for contact with foodstuffs | Special types | - |

| EMC** | Yes, field-dependent shielding | - |

| Water absorption | From <3.5%, can be made hydrophobic | - |

| Other | - | Free from silicone, isocyanates, halogens and solvents. |

* RTV (Room Temperature Vulcanisation), hardening through air humidity, different from 2-component systems

** Shielding dB (manufacturer specifications): Magnetic field (10kHz) - 67, Electric field (1 MHz) - 130, Polarisation density (1Ghz) - 110