Keeping it sealed

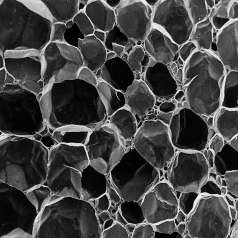

Cellular rubber

Cellular rubber made by KÖPP is the ideal material for sealing, insulating, isolating, damping and rattle prevention. That is why this cost-effective material is used successfully throughout industry. The material can be supplied in blocks, sheets or rolls. It can be punched, milled or customised to your requirements. It is also available in a self-adhesive a self-adhesive version. KOEPPcell® cellular rubber can be processed in many different ways.

Questions? Answers!

Areas of application

Cellular rubber - the material

Cellular rubber is a porous, closed-cell rubber quality, which is available in various resistance ratings and densities. It is manufactured using the expansion process. It is based on natural rubber or synthetic rubbers such as EPDM and other elastomers.

Cellular rubber is airtight and watertight, so it does not need any external skin to be used as a seal (unlike sponge rubber).

Our KOEPPcell® range offers you the following types of cellular rubber and elastomers, with our usual high quality at competitive prices:

- Natural rubber (NR-L, NR-S)

- EPDM (EPDM-i, EPDM-L*, EPDM-S*, EPDM-SUW*, EPDM-W*)

* all also peroxide-cured - Chloroprene rubber (CR-M, CR-H, CR-F)

- Nitrile rubber (NBR)

- EPDM-PE blend, EPDM-EVA blend

- Mixed-cell (semi-closed) EPDM (EPDM-SC-W, EPDM-1000)

You can download our data sheets on cellular rubber from our Service Centre.

Technical data

It meets a huge variety of requirements

As a manufacturer and dealer, we can offer you an outstanding variety of different qualities and resistance levels for you to choose from on the basis of the focus of your application and your requirements. The following are the most important properties:

- Outstanding sealing

- Low thermal conductivity value (≤ W 0.1 W/mK)

- High compressibility

- Good insulating properties

- Low water absorption

- Flexible processing options

- Can be sulphur or peroxide-cured

- High resistance to temperature and ageing (EPDM)

- Highly flame-resistant and oil-resistant (CR/NBR)

- High elasticity (NR)

- Economical, as it comes straight from the manufacturer

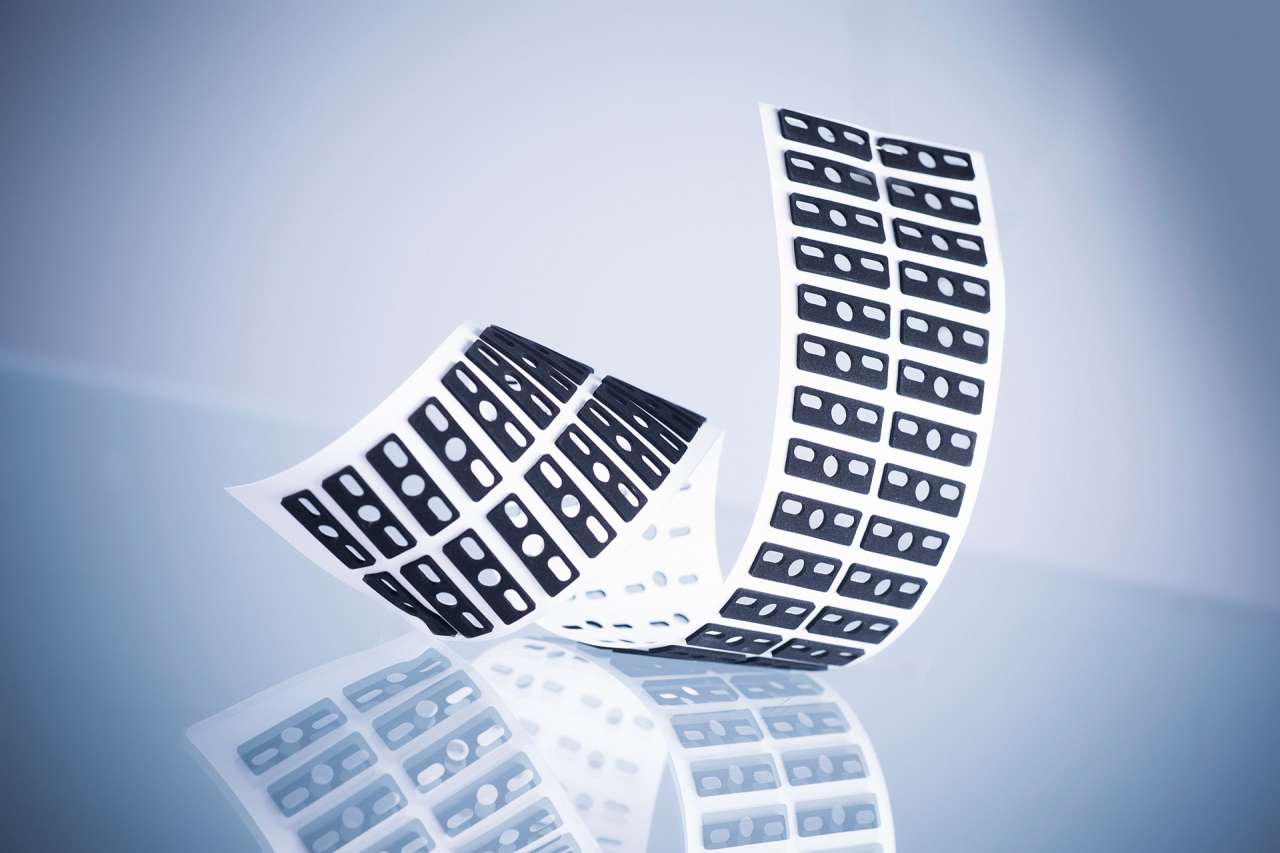

Processing methods

Perfect semi-finished products – good news for our customers

We process our own cellular rubber blocks for our processing customers in such a way that they can include them directly in their production procedures. We have a broad selection of machine tools installed, so we are in a position to supply sheets and endless rolls. We can split precisely from 1 mm thicknesses and apply various adhesive coatings on request.

Depending on the intended use, we also process the plates and rolls into cut pieces, punched parts, strips, profiles, turned and milled parts for dealers and end users in industry. Processing on water jet cutting systems is also possible.

Materials

NR

Natural rubber (NR) in its pure form is used in countless everyday products. Hardly any other material offers values as high as natural rubber for tensile strength, tearing strength, elasticity and low-temperature flexibility. For this reason it is an indispensable component in the tyre industry for lorries, cars and aircraft tyres, for shoe soles or dip-moulded products such as gloves and even condoms.

These outstanding qualities are also to be found in our natural rubber-based cellular rubber products. Natural rubber offers the best compression set of all the elastomers.

EPDM

EPDM, a synthetic rubber, is the elastomer all-rounder. It stands out for its high resistance to external influences such as ozone, light and water, so it is particularly appropriate for outdoor use. It also has good acid and alkaline resistance and high tensile strength. EPDM products can be used across a wide range of temperatures. The are still very flexible in cold conditions and they can withstand a maximum temperature of up to 140°C while under constant stress.

EPDM is used for manufacturing construction profiles, cable insulation and hoses (including for hot air and hot water), for example. It is a common sealing material in many industries.

CR

Chloroprene rubber (CR) is a synthetic rubber with impressive fire-resistant behaviour. CR materials are self-extinguishing, so they are used in areas with high fire risk. CR is also highly resistant to brittleness, the elements and saltwater. Known as

Neoprene, CR rubber is used for diving suits and heat-insulating sports clothing, for example. Further applications include sealing, cable sheathing or technical hoses and conveyor belts or drive belts in the automotive sector.

NBR

Nitrile rubber (NBR) is a synthetic rubber with very high resistance to oil, fuels and a wide range of chemicals. Compared to other elastomers, NBR has high abrasion resistance even at high temperatures, and it is very hard-wearing.

Its good mechanical properties and low compression set make NBR the ideal material for automotive and aeronautical applications, e.g. oil-resistant seals, braking systems or conveyor belts, and also for protective gloves, hoses and O-rings.

EPDM-PE blend

This high-quality blend of cellular rubber and polyethylene combines all the positive properties of rubber and PE. It has the high elasticity and fine-celled, velvety surface of a pure EPDM and the high temperature resistance of a pure polyethylene.

This means that the blend is suitable for a variety of applications.

EPDM semi-closed

Mixed-cell (semi-closed) cellular rubber, such as our EPDM SC-W or our EPDM-1000, is mainly used for demanding applications in various sealing areas, especially in the automotive sector. The open cells are the basis for the softness, while the closed cells are responsible for the tightness.

The very soft material is excellent for compression and achieves its tightness at 40% deformation.

EPDM-CR

An EPDM-CR blend has improved resistance to chemical media thanks to the combination of EPDM and chlorinated rubber (CR). The material still retains the excellent weather resistance of EPDM.

The addition of CR improves not only the chemical resistance but also the fire behaviour. An EPDM-CR blend is suitable for many applications where a pure CR is not necessary.

Applications for cellular rubber

One solution for many markets

Thanks to its reliable performance for sealing, insulating, isolating and padding, KÖPP cellular rubber is to be found in virtually every area of life. This includes the automotive sector, construction, mechanical engineering, and the furniture and textile industries.

Manufacturing for over 45 years

KÖPP has a long history of in-house cellular rubber production. Our high-quality products – developed in Germany and cost-effectively produced in Romania using the latest technology – make us the top supplier among the few cellular rubber manufacturers, and our range of KOEPPcell® materials is constantly growing. This means our customers get top quality products at an attractive price.

We can offer a much better service than other manufacturers because we have so many ways of making products to meet our customers’ requirements. Make the most of our unique combination of manufacturing expertise, extensive storage logistics, high storage availability and flexible delivery, varied processing and preparation of semi-finished products.