Reliable quality

Filter technology

Since 1965 KÖPP’s filter technology department has been offering its customers personal bespoke solutions including a wide selection of filter equipment for liquid filtration, filter material for filtration, separation, ventilation and venting and silencers.

This established company from Aachen has achieved this using high-quality VYON® and GURON® filter materials – open-pore low-pressure polyethylenes with outstanding properties such as physiological safety, temperature resistance, high corrosion and chemical resistance, lightweight, environmental friendliness and a good cost-benefit ratio. These are the reasons why KÖPP filter materials have been successful for decades.

You have questions? We look forward to getting in contact with you.

Your Filter technology expert:

Laure Walter

filter@koepp.de

+49/241/16605-12

Filter materials

Positive properties across the board

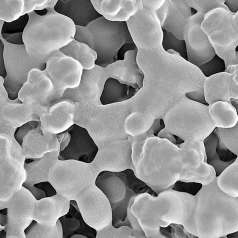

The filter materials VYON® and GURON® are sintered, porous low-pressure polyethylenes, with polymer particles that fuse together at their contact points. This creates a porous material, which is highly effective for filtration, ventilation/gassing, soundproofing or protection, e.g. as a flame-retardant insert in vehicle batteries or for soundproofing in membrane pumps or compressed air applications. VYON® and GURON® are used for medical equipment in a huge variety of analytical devices e.g. for preparing human and animal DNA. GURON® moulded parts are used in orthopaedic technology, e.g. in joint inserts for advanced prosthetics.

VYON® filter frits have proven their worth in analytical applications such as solid phase extraction columns (SPE columns). Here, they hold the sorbent securely between the two precise VYON® stampings. In flash chromatography cartridges, on the other hand, precisely dimensioned VYON® cartridge frits enclose the sorbent powder. The column frits also have excellent strength and enable a uniformly high flow rate.

It is also used in the paper industry and for measuring and sensor equipment: wherever there is a need for ventilation venting, protection, filtering or damping.

The range also includes porous sintered polypropylene and porous sintered PTFE.

Moulded parts

GURON® moulded parts are made primarily to customer specifications. The material can be moulded to practically any shape. Each moulded item is sintered. This means that we can manufacture parts with average pore gauges ranging from 5 µ to 300 µ.

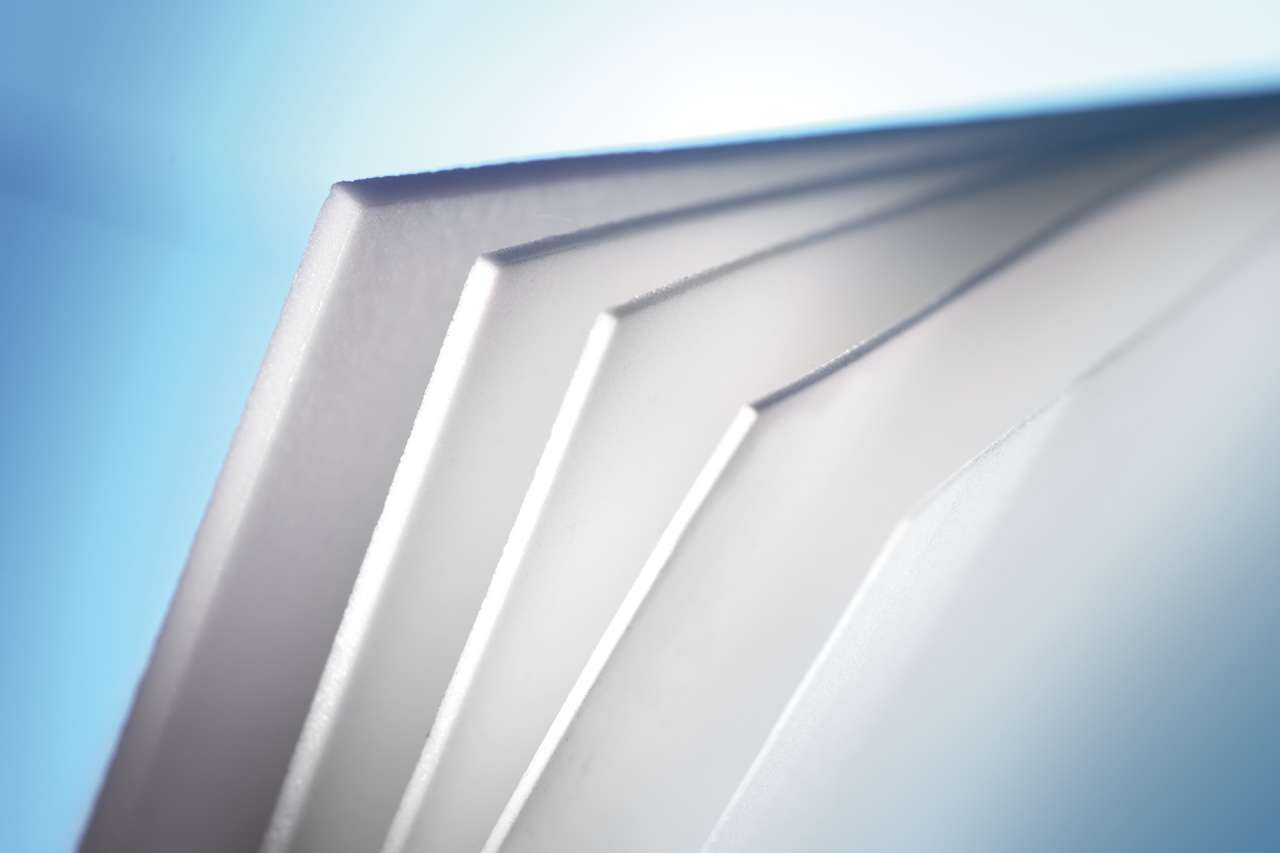

Sheets/rolls

VYON® rolls and sheets as semi-finished products are particularly suitable for making strips, cut-to-size parts and punched items.

Special welding technology can be used to produce filter pipes up to 2 m in length.

Silencers

Noise is a danger to health. For this reason noise reduction is an important part of work safety.

Thanks to their porous structure, VYON® and GURON® are highly suited to soundproofing, reducing noise by up to 30 dB.

Furthermore, VYON® silencers are also suitable for ventilation and filtration.

VYON® silencers with screw fitting and hose fitting

| Connector sizes | Ø mm | Length of sintered body with collar | Overall length incl. thread |

|---|---|---|---|

| 1/8” | 12.85 +/-0.75 mm | 27.8 +/-1.2 mm | 34.5 +/- 1 mm |

| 1/4” | 16.6 +/- 0.5 mm | 35.7 +/-1.2 mm | 42.6 +/-1 mm |

| 3/8” | 24.4 +/-1 mm | 57.4 +/-1.2 mm | 67.5 +/-1 mm |

| 1/2” | 24.8 +/-1 mm | 68.0 +/-1.2 mm | 78.5 +/-1 mm |

| 3/4” | 37.6 +/-0.5 mm | 124.8 +/-1 mm | 139.8 +/-1 mm |

| 1“ | 47.8 +/-0.8 mm | 124.8 +/-1 mm | 154.0 +/-1 mm |

| Push-in silencers | Ø mm | Length of sintered body with collar | Overall length incl. thread |

|---|---|---|---|

| 4 mm | 7.5 +/-0.5 mm | 16.0 +1/-2 mm | 32.0 +2/-4 mm |

| 6 mm | 12.5 +/-0.5 mm | 24.5 +/-1.5 mm | 45,0 +/-3 mm |

| 8 mm | 13.5 +/-0.5 mm | 22.0 +/- 1.5 mm | 43.5 +/-3 mm |

| 10 mm | 15.5 +/- 0.5 mm | 31.0 +/-1.5 mm | 57.5 +/-3 mm |

| 12 mm | 18.5 +/-0.5 mm | 53.0 +4/- 2 mm | 82,0 +4/-2 mm |

Filter equipment

A broad range of products to suit all needs

When our drinking water leaves the waterworks it is clean and free from contaminants. Unfortunately as the water travels through the supply network to our homes it picks up dirt particles along the way, which can lead to unpleasant malfunctions and stoppages which can mean costly downtime for machines, pumps, valves or household devices to name but a few examples. Fitting a filter ensures that damaging particles are kept out. This allows you to avoid operation stoppages and expensive repairs.

Very varied demands are made of reliable filter technology. KÖPP responds with a comprehensive selection of reliable filter equipment. Special versions can also be supplied. Bespoke solutions to meet all needs – that’s KÖPP. The same applies for filter technology.

Our filter equipment

You can find a complete overview of all filters with technical data, specifications, installation instructions and replacement parts at the Service Centre.